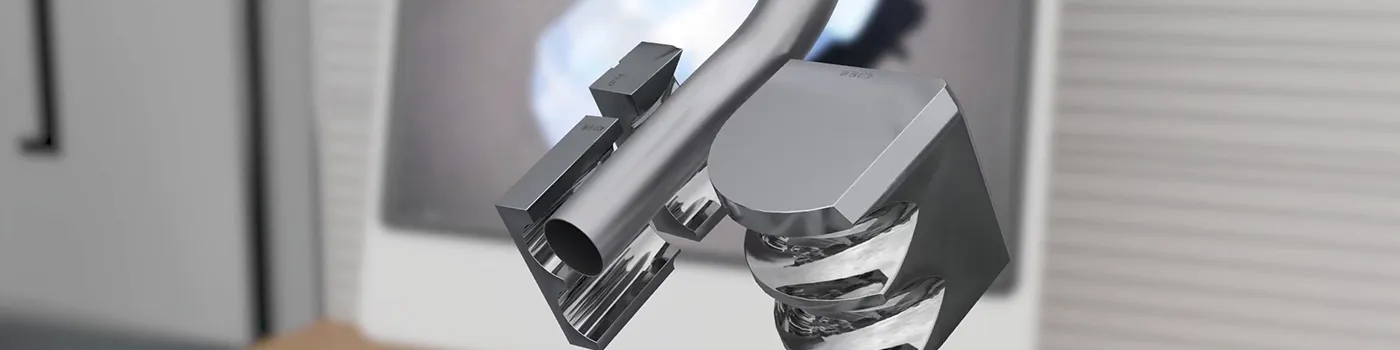

16-Axis Double-Station 3D Laser Cutting Machine

Robotic 3D laser processing system consisting of two 6-axis laser cutting heads and four rotary axes

16-axis double-station 3D laser cutting machines are designed for high-precision processing of complex metal parts, including irregular tubes, automotive body components, hot-formed steel parts, and shaped metal profiles. Coordinated multi-axis motion and two independent laser cutting heads allow different parts to be processed simultaneously, improving efficiency without compromising accuracy. User-friendly controls and an upgraded cutting parameter library make it easy to adjust and modify cutting paths, while the dual-station, multi-axis layout helps significantly increase overall production capacity.

| Specification | ||||||||||||||||

| Travel | 2950 mm | 2950 mm | 1380 mm | 1380 mm | 730 mm | 730 mm | ±180° | ±180° | ±180 | ±180° | ±135 | ±135° | NX360° | NX360° | ±10 mm | ±10 mm |

| Maximum Speed | 120 m/min | 120 m/min | 80 m/min | 80 m/min | 120 m/min | 120 m/min | 120RPM | 120RPM | 120RPM | 120RPM | 120RPM | 120RPM | 120RPM | 120RPM | 20 m/min | 20 m/min |

| Maximum acceleration | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 10 m/s² | 25 rad/s2 | 25 rad/s2 | 25 rad/s2 | 25 rad/s2 | 125 rad/s2 | 125 rad/s2 | 125 rad/s2 | 125 rad/s2 | 10 m/s² | 10 m/s² |

| Repeatability | ±0.025 mm | ±0.025 mm | ±0.015 mm | ±0.015 mm | ±0.015 mm | ±0.015 mm | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.01° | ±0.025 mm | ±0.025 mm |

| Motor power | 5 kW | 5 kW | 5.5 kW | 5.5 kW | 5.5 kW | 5.5 kW | 0.62 kW | 0.62 kW | 0.62 kW | 0.62 kW | 0.37 kW | 0.37 kW | 0.75 kW | 0.75 kW | 0.2 kW | 0.2 kW |

| Laser power | 6000 W | |||||||||||||||

| Maximum fixture load | 100 kg (Note: fixture center of gravity 200 mm from axis center) | |||||||||||||||

| Overall dimensions (L × W × H) | 6800×4300×5200 mm | |||||||||||||||

| Total weight | Approx. 30 T | |||||||||||||||

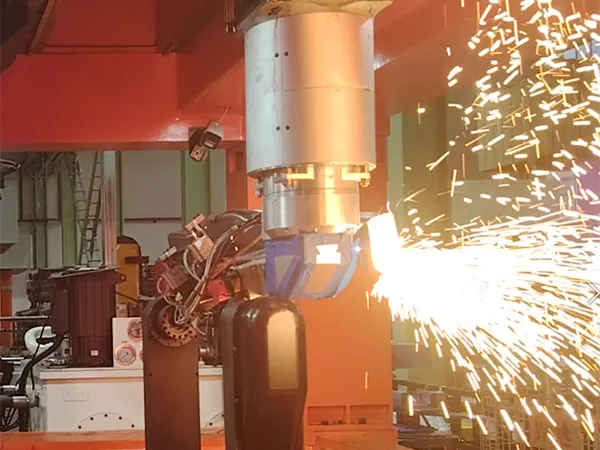

3D laser cutting solutions are widely used for precision processing of carbon steel, stainless steel, titanium alloys, and aluminum alloys across industries such as automotive manufacturing, aerospace, rail vehicles, medical devices, and sheet metal fabrication.

Irregular tubular parts

Automotive chassis components, motorcycle frames, automotive exhaust systems, and fitness equipment.

Stamped body and cover parts

Automotive body panels, tooling samples, vehicle cabins, and new energy vehicle components.

Hot-formed steel components

Roof cross members, lower body structures, side reinforcement panels (A, B, and C pillars), and front bulkhead panels.

Independent dual-path processing

Most 5-axis 3D laser systems rely on a single cutting head, which often requires irregular tubes to be re-clamped to complete the cutting process. This extra handling can affect accuracy. Two independent cutting heads, combined with a 16-axis configuration and four external rotary axes, allow complex parts to be processed in a single setup. By completing the cutting process in a single setup, positioning errors are reduced and cutting accuracy remains stable and consistent.

High-speed dual-path following control

During laser cutting, the distance between the cutting head and the material needs to stay constant. If the surface height changes, the cutting head has to move accordingly, otherwise cutting quality is affected. This system uses FANUC high-speed following control (HSP), which allows the cutting heads to adjust their position instantly as the surface changes, keeping the cutting gap stable throughout the process.

Efficient programming

- The laser cutting center and the actual workpiece position are mirrored in the software on a 1:1 basis. Programming and testing can start earlier, without waiting for fixture completion or going through time-consuming three-point positioning during setup.

- Fully automated path optimization is integrated into the 5-axis programming process, addressing collision risks and axis limit constraints while lowering programming complexity and improving efficiency.

- Motion simulation generates spatial sweep volumes that record the movement of the cutting head, fixtures, and related components. Interference zones can be identified more easily, supporting fixture designs that better match the actual working space required for machining.

Independent dual-path process settings

Dual-channel control allows each cutting path to be set independently, with up to 30 parameter sets per channel, making process adjustments much simpler when conditions change. Power waveform control helps avoid burrs at corners and reduces the risk of overheating, which keeps quality consistent on complex shapes. Processing levels can be adjusted from 1 to 10, where higher levels focus on precision and lower levels allow faster cutting speeds. Different processing levels can also be applied to the same tube, allowing speed and precision to be balanced according to the specific cutting requirements.

Efficient double-station automated processing

Dual-station robotic loading and unloading keep the system running continuously, reducing manual handling and cutting down on loading time.