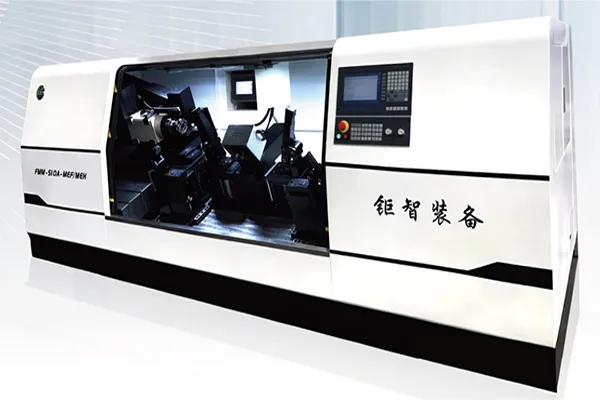

CNC Milling Machine for Automotive Subframe & Chassis Parts

CNC milling machines for automotive subframe and chassis parts are built for high-precision machining of frame structures. The milling machine uses a BT50 high-power spindle and a rigid cross-slide guideway design to ensure stable cutting performance. Milling feed is controlled by a Bosch Rexroth MTX micro CNC system with original Rexroth servo motors, while FAGOR high-precision linear encoders provide closed-loop feedback for accurate position control. Milling pin surfaces are monitored using four Panasonic HG1 laser displacement sensors, with measured data processed by the PLC to calculate the required beam and tilt angles. An automatic lubrication system ensures proper lubrication of moving components, and an automatic chip removal system keeps the machining area clean during operation.

| Item | Specification |

| Overall dimensions (L × W × H) | 4050 (excluding chip conveyor) × 1750 × 1650 mm |

| Total power | 30 kW |

| Operating voltage | Three-phase, two-wire, 380 V ±5% |

| Pneumatic-hydraulic clamping force | > 2000 kg |

| Left front toe angle | 0.13° ±0.1° |

| Right front toe angle | 0.13° ±0.1° |

| Left camber angle | 1.09° ±0.3° |

| Right camber angle | 1.09° ±0.3° |

- Before the machining process starts, the CNC milling machine checks how much material is left on the part and removes only what is needed to meet the required dimensions.

- After finishing, the end face is automatically inspected for tilt angle and bevel angle. Inspection data is stored, and parts are marked only after passing the check.

- Bevel and tilt angles on the milled end face can be adjusted through servo motor control, with an adjustment range of ±3°.

- CNC-controlled servo feeds allow the feed position to be adjusted easily and accurately on the machined surface.

- The 25° inclined table, together with a chip conveyor, enables automatic chip removal and keeps the machining area clean.

- Pneumatic-hydraulic clamping system

- CNC rotary table with self-locking system

- Automatic lubrication system (reservoir type)

- Rigid slide table and drive assembly

- Laser displacement measurement system

- Automatic chip removal system

- MTX micro control system (including servo drives, HMI, and leakage protection)

Automotive rear subframe machining

Rear subframes are one of the key structural parts of a vehicle, and their accuracy has a direct impact on handling, safety, and durability. CNC milling machines are generally used to machine surfaces and mounting points, so the subframe fits correctly with other chassis components and maintains consistent dimensions during vehicle assembly.