We develop and manufacture complete production-line equipment for lightweight, high-strength tubular chassis components. Each production line integrates tube bending equipment, tube hydroforming presses, and laser cutting systems, with core equipment designed and built in-house. Direct control over equipment design, process flow, and tooling ensures alignment with the actual production requirements of automotive tubular chassis components.

-

- CNC Tube Bending Machine

- Angle: 13-axis full-servo bending ensures accurate control at any bending angle, with angular accuracy within 0.05° and feeding accuracy up to 0.05 mm.

- Circularity: Multi-core mandrel bending combined with synchronized lubrication helps maintain stable tube roundness during the bending process.

- Thinning: Wall thinning is managed by coordinating the bending motion with auxiliary pushing and mandrel movement. Push-feed compensation and synchronized lubrication help keep wall thickness more consistent and improve forming stability.

-

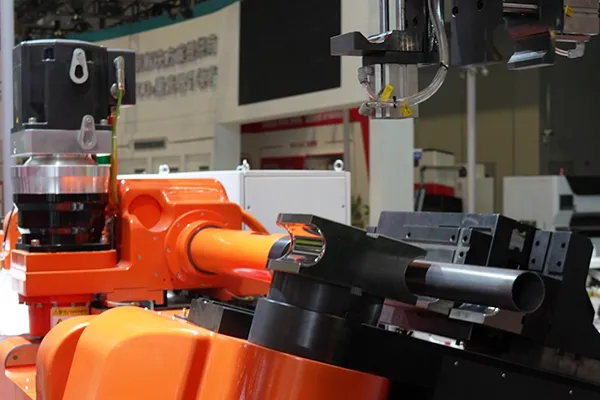

- CNC Tube Hydroforming Press

- Ultra-high-pressure capability: Each hydroforming press is equipped with two intensifier cylinders, which allows internal pressure to reach up to 400 MPa. This pressure level allows tube hydroforming presses to handle complex parts with large deformation and high yield strength.

- Accurate pressure control: Pressure control at the intensifier cylinders is maintained within ±0.5 MPa, meeting the precision requirements for tube hydroforming processes.

-

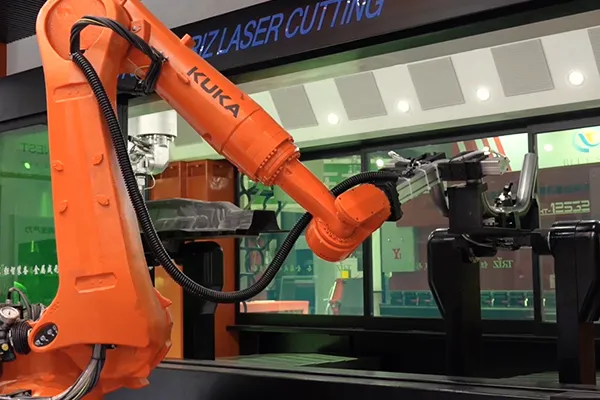

- Double-Station 3D Laser Cutting Machine 16-axis double-station 3D laser cutting machines are designed for high-precision processing of complex metal parts, including irregular tubes, automotive body components, hot-formed steel parts, and shaped metal profiles. Coordinated multi-axis motion and two independent laser cutting heads allow different parts to be processed simultaneously, improving efficiency without compromising accuracy.

-

- Laser Tube Welding Line (Pipe & Tube Mills)

- High laser power: Laser welding power ranges from 15000W to 45000W, suitable for stable welding of different tube sizes and thicknesses

- High welding speed: Production speeds can reach up to 15 m/min, supporting continuous and efficient tube manufacturing

- High welding accuracy: Weld seam deviation is controlled within 0.1 mm, helping keep consistent weld quality

-

- Laser Scanning 3D Inspection Equipment 3D laser scanning systems are used to capture the full surface geometry of metal parts with high accuracy. The 3D laser scanning and inspection system combines a laser scanner with a robotic arm and servo-driven motion, allowing complex parts to be scanned automatically as the robot follows a preset path.

-

- CNC Milling Machine CNC milling machines for automotive subframe and chassis parts are built for high-precision machining of frame structures. The milling machine uses a BT50 high-power spindle and a rigid cross-slide guideway design to ensure stable cutting performance. Milling feed is controlled by a Bosch Rexroth MTX micro CNC system with original Rexroth servo motors, while FAGOR high-precision linear encoders provide closed-loop feedback for accurate position control.

Our Valued Customers