20 Years of Expertise in Hydroforming & Tube Processing

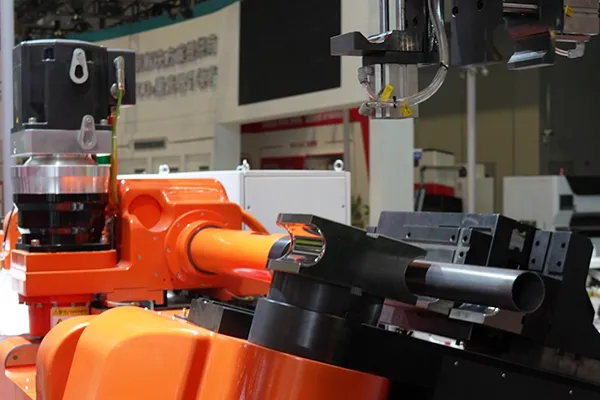

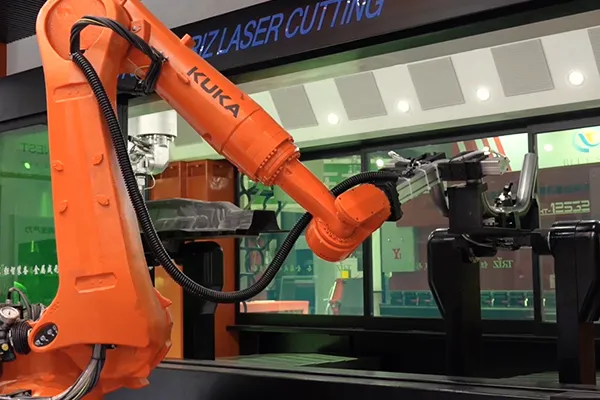

At Motorbacs, we provide high-precision tube processing and hydroforming solutions designed to meet the evolving demands of the global automotive industry. Our offerings include a variety of hydroformed chassis components and advanced tube processing equipment like CNC tube bending machine, 4000T hydroforming presses, and 16-axis laser cutting and welding systems.

Our Valued Customers