Cases

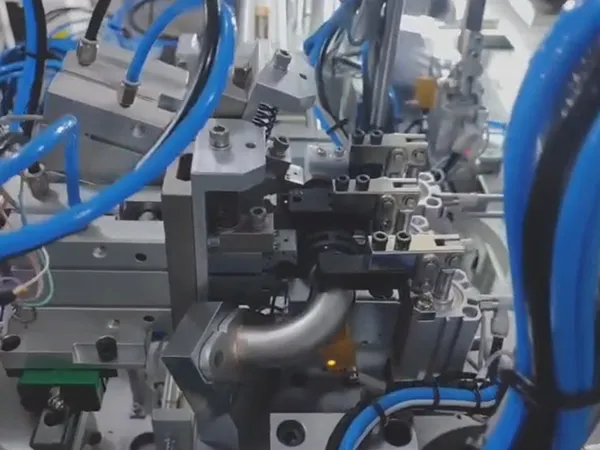

Taking the BYD fifth-generation DMI engine pipe production line as an example, a fully customized and integrated automated workstation was developed to replace traditional manual production, significantly improving efficiency and reducing labor costs. This success has paved the way for expanding automation to additional production projects in the future. Following implementation, product share increased from 34% to 75%, demonstrating clear advantages in capability, stability, and competitiveness.

-

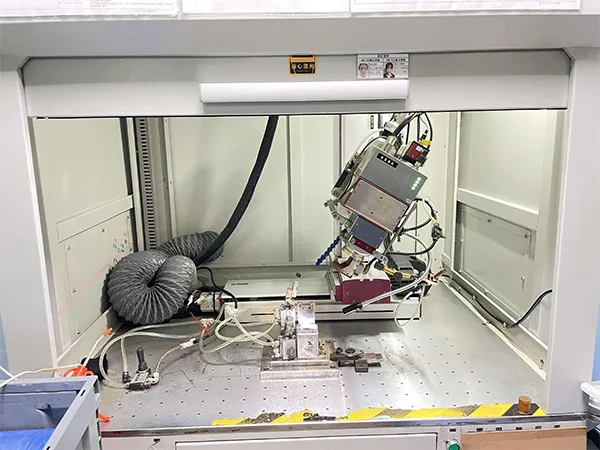

Laser Welding

Laser Welding -

Automatic Coating

Automatic Coating -

Brazing

Brazing -

Component Inspection

Component Inspection -

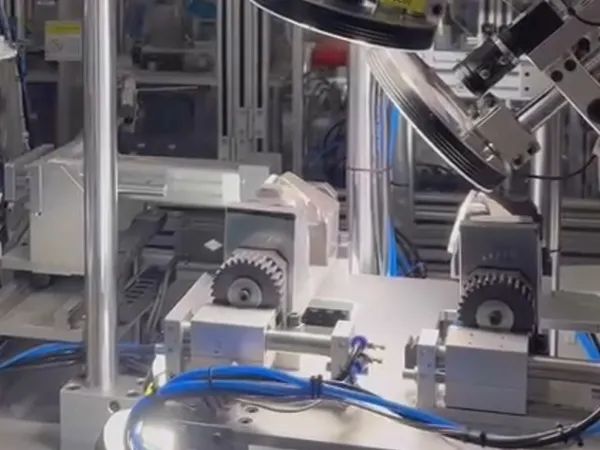

Workstation: Assembly + Air leak test + Appearance inspection + Marking

Workstation: Assembly + Air leak test + Appearance inspection + Marking -

Packaging

Packaging

Our Partners