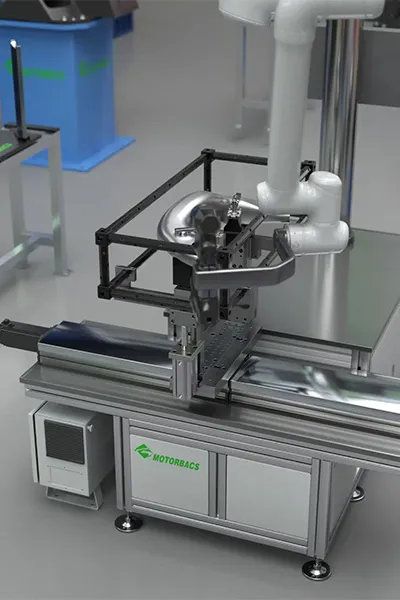

Motorbacs develops chassis structural solutions by combining tubular integration design, process optimization, and manufacturing efficiency, enabling automotive manufacturers to achieve weight reduction and cost control without compromising durability or reliability. Alongside the development, we integrate equipment engineering and digital manufacturing technologies, including 5G-enabled industrial connectivity, to support intelligent and highly automated production. To support these capabilities, we independently design and manufacture complete production line equipment for lightweight tubular chassis components. This includes in-house development of tube bending equipment, tube hydroforming systems, and laser cutting systems, allowing full control over key forming and processing stages. By aligning advanced equipment engineering with chassis component development, we bridge high-end manufacturing systems with the practical demands of lightweight, high-strength automotive chassis structures.

Through integrated product development, equipment manufacturing, and intelligent production systems, Motorbacs continues to support automotive customers in building more efficient, lightweight, and manufacturable chassis architectures for next-generation vehicles.

- 20+ years of expertise in tube hydroforming

- 80,000+ square meters of advanced manufacturing facilities

- 10,000,000+ automotive engine tubes produced annually

- 20,000,000+ sets of hydroformed chassis parts produced annually