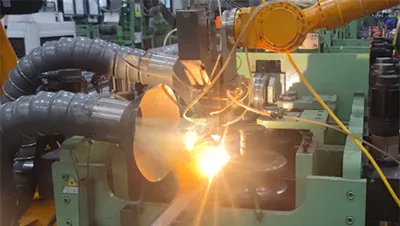

High Speed Laser Tube Welding Line (Pipe & Tube Mills)

Integrated laser welded tube production system for metal tubular parts in automotive and industrial applications, with up to 15m/min speed and 0.1mm seam accuracy

- Laser power: 15000–45000 W

- Welding speed: 8–15 m/min

- Weldable material strength: > 800 MPa

- Weldable material thickness: < 4 mm

- Welding accuracy: < 0.1 mm

- Material yield: > 96%

- Tube deformation after welding: ≤ 1.5 mm/m

- Weld seam strength: No cracking after flaring test, compliant with GB/T 34204-2017

Process Flow

Uncoiling & straightening → Shear butt welding → Accumulator storage → Strip leveling → Edge milling → Rough forming → Fine forming → Weld seam tracking → Laser cleaning → Laser preheating → Laser welding → Laser post-heating → Sizing → Eddy current testing → Tube straightening → Laser marking → Length cutting → Automatic stacking → AGV transport → Finished product storage

- Weld quality control

Weld seams need to be consistent in appearance and strength, and meet strict performance requirements. Common issues such as porosity, cracks, incomplete penetration, burn-through, and welding distortion must be carefully avoided. - Equipment complexity

Laser welding lines combine many systems into one process, including loading, edge milling, tube forming, laser welding, cut-to-length units, online eddy current testing, and robotic unloading. Coordinating mechanical, electrical, optical, and material-related technologies adds a high level of technical difficulty. - Control system stability

To maintain welding efficiency and consistent quality, the system relies on advanced automation and intelligent control to keep the process stable during production. - Automation and intelligent control

Welding parameters need to be adjusted accurately and in real time to match different production conditions. Advanced automation and intelligent control are important to keeping the process efficient and repeatable. - Material adaptability

Welding equipment should be able to handle a wide range of materials, tube diameters, and wall thicknesses, especially when working with ultra-high-strength steels above 800 MPa.

- High-precision drive and motion control

Stable welding speed is achieved through the use of 15 high-precision servo drive units, combined with adaptive control and real-time feedback. This setup allows the system to respond quickly to changes during welding and keep motion smooth and consistent. - Machine vision and sensing technology

Cognex machine vision and sensors keep track of the weld seam while welding is in progress. They help spot defects early and feed the information into our monitoring system, so the welding process stays under control. - Integrated development of advanced laser welding technologies

Improving welding efficiency and quality requires the deep integration of automation and intelligent control. Development focuses on high-speed laser welding (up to 15 m/min) and high-power laser processes (multi-kilowatt range) for high-strength steel tubes. Key efforts include weld seam tracking, high-speed and high-accuracy alignment, defect control, and forming accuracy. Structural simulation of lightweight components and performance evaluation are also part of the development process, supporting the creation of fully automated laser tube welding lines for high-strength steel.

Real-time welding speed monitoring

Sensors and feedback systems monitor welding speed during operation and adjust it in real time to keep it within the required range.

Parameter optimization through testing

Different welding speeds are tested through several trial runs to find the most suitable speed and acceleration settings. These settings are then refined through repeated adjustments and testing, until the welding process reaches stable and accurate speed control.

High laser power

Laser welding power ranges from 15000W to 45000W, suitable for stable welding of different tube sizes and thicknesses.

High welding speed

Production speeds can reach up to 15 m/min, supporting continuous and efficient tube manufacturing

High welding accuracy

Weld seam deviation is controlled within 0.1 mm, helping keep consistent weld quality

High-strength steel compatibility

Designed for welding high-strength steel grades above 800 MPa, commonly used in automotive applications

High material yield

Material utilization exceeds 96%, helping reduce scrap and improve overall production efficiency