Hydroformed Frame Rails & Crossmembers for BOF

Hydroformed chassis components for body-on-frame chassis systems in off-road and heavy-load applications

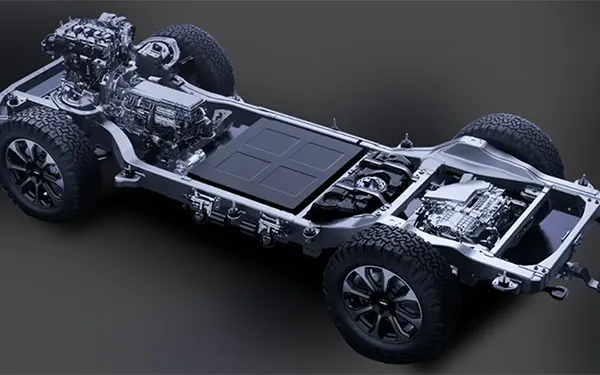

In body-on-frame chassis systems, the vehicle load is carried by an independent frame. Hydroformed frame rails and crossmembers form the core structure and are designed to handle heavy loads and harsh conditions, such as off-road use and cargo transport. These hydroformed components are designed to stay strong and reliable, even when operating under heavy loads and harsh conditions.

- Tube diameter Ø45–Ø160 mm

- Length up to 2400 mm

- Wall thickness 1.8–7.5 mm

Core Design

- Section design: high load capacity with reduced weight

Hydroformed frame rails offer much higher torsional and bending strength than traditional open-section rails, improving torsional stiffness by over 40% and bending strength by more than 35%. Variable cross-sections can be used based on load differences, achieving over 20% weight reduction without compromising strength. - Rail-to-crossmember connection: reduced stress concentration

Rails and crossmembers are shaped by hydroforming and only welded where necessary. That way, the frame stays strong on rough roads and under torsion, without creating stress concentration at the connections.

Samples

Product Advantages

- Strong load-bearing capability

Compared with conventional frame rails, hydroformed frame rails are more resistant to twisting and bending, which is suitable for trucks over 50 tons and for off-road vehicles exposed to heavy torsional loads. - Weight reduction with cost benefits

A 15–25% weight reduction compared to traditional frame rails helps cut fuel use and material costs. - Long service life

With more than 60% fewer weld points and added shot peening treatment, fatigue life is increased by 25–30%, meeting durability requirements of up to 10 years or 1 million kilometers. - Easy customization

Reserved mounting points allow easier adaptation for special-purpose vehicles such as construction vehicles and RVs, reducing the need for additional machining after assembly.

Production Capabilities

- Four 5,000-ton hydroforming lines are dedicated to frame rails, running with MES and smart warehousing to support fully automated production and maintain yield above 99%.

- A self-developed 168# large-diameter tube bending machine supports precise pre-forming of heavy-duty frame components.

- Proprietary 5,000-ton hydroforming presses provide sufficient forming pressure and clamping force for large BOF frames. Reference surface flatness is controlled within ≤0.15 mm, while profile and forming tolerances are kept within ±0.5 mm.

- In-house 32-axis laser cutting systems allow all features to be cut in a single setup, reducing positioning errors and improving overall accuracy.

- Inline laser scanning systems are used to check each part against dimensional requirements during production.

Applications

- Heavy-duty trucks, such as tractor units and dump trucks, where the frame needs to carry very high loads every day without cracking or losing stiffness over time.

- Off-road vehicles, including pickups and dedicated off-road models, that are constantly exposed to twisting and uneven terrain and need a frame that won’t deform easily.

- Special-purpose vehicles, such construction trucks, rescue vehicles, or RV chassis, where both load capacity and flexibility for customization really matter.

- Military vehicles, from off-road transport to armored platforms, designed to stay reliable in harsh environments and under demanding operating conditions.