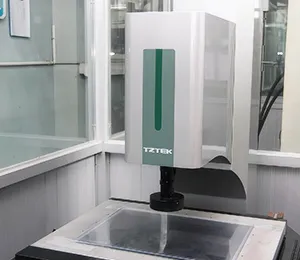

Motorbacs adopts a full lifecycle quality management approach, establishing a scientifically structured quality assurance system. With the deep application of laser scanning technology as a core strength, supported by multi-dimensional control measures, we have built a strong reputation for reliable and high-standard quality performance across the industry.

- Standardized control across the entire process

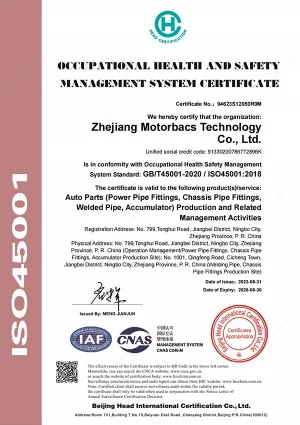

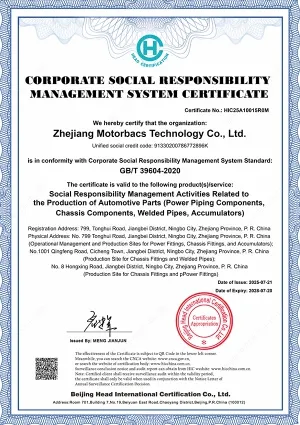

Quality management covers every stage from raw materials, production, and finished products to after-sales. Raw material inspection achieves a 100% rate, finished product inspection exceeds industry standards by more than 20%, and full-chain traceability is ensured through unique identification management. - Company-wide quality culture

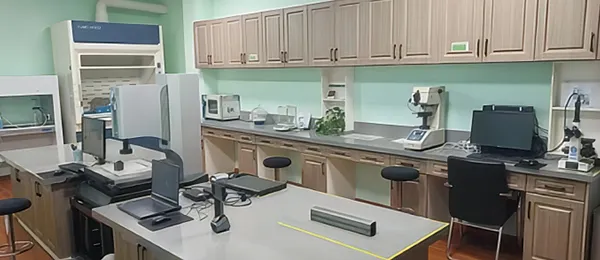

A company-wide individual accountability system is implemented, where clear quality responsibility is assigned to specific roles across each process, supported by incentive mechanisms. More than 200 employee improvement initiatives are implemented annually, contributing to a 40% reduction in human-error-related quality issues. - Advanced inspection equipment matrix

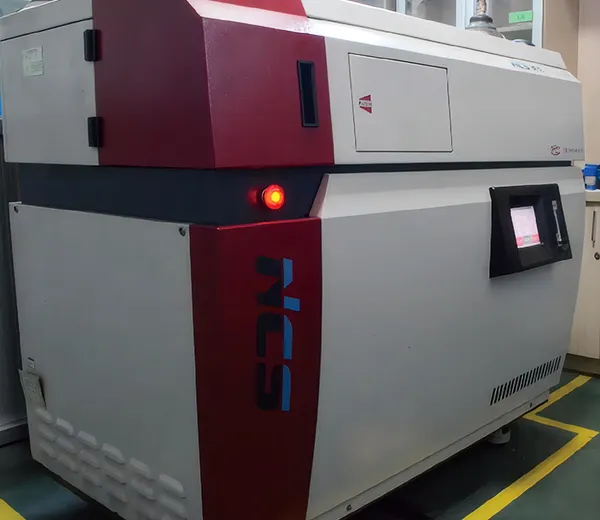

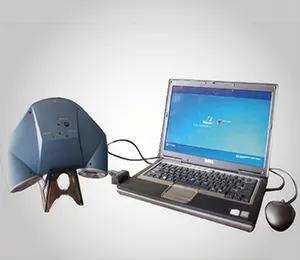

In addition to laser scanning technology, the company is equipped with coordinate measuring machines (CMM), spectrometers, and non-destructive testing systems, ensuring precise, comprehensive, and reliable inspection coverage without blind spots. - Continuous improvement

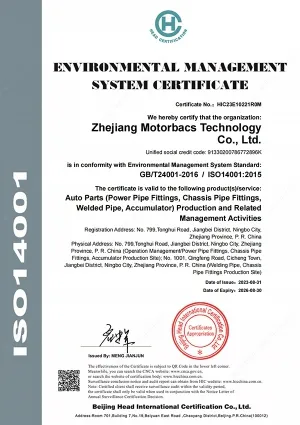

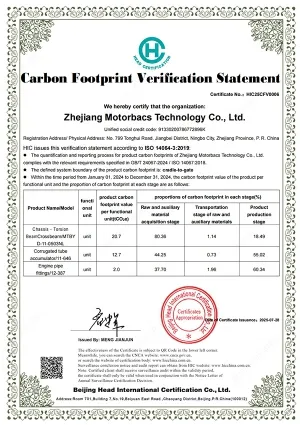

Quality management follows the PDCA cycle, evolving alongside market standards and regulatory requirements such as environmental compliance. More than 90% of product output is classified as environmentally friendly.