The Modo Technology Center was established in April 2022 and currently consists of more than 80 professionals. It is organized into two major divisions: the Project Department and the Engineering Technology Department.

The Project Department includes the Project Review Section, New Project Development Section, Mass Production Project Section, and Supplier Development Section. The Engineering Technology Department comprises the Modeling & Analysis Section, Tooling & Mold Technology Section, Tooling & Fixture Section, Production Line Planning Section, Manufacturing Engineering Section, Process Implementation & Standard Cost Section, and Testing & Laboratory Section.

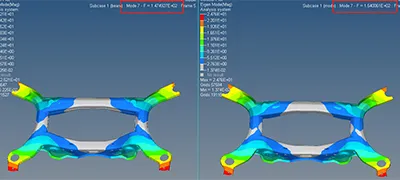

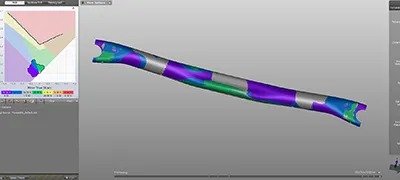

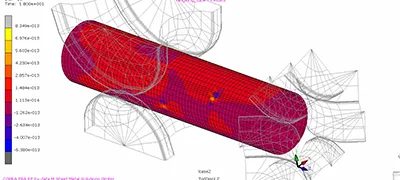

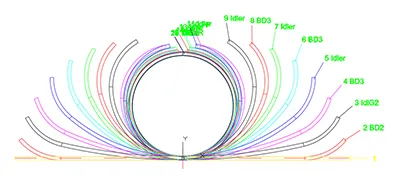

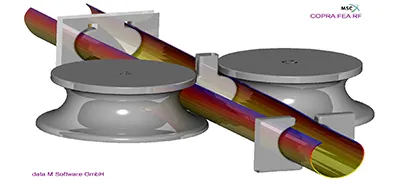

The Technology Center integrates multiple core functions, including product design, simulation, and prototype development; tooling design, simulation, and manufacturing; production line design, simulation, and implementation; new project development; mass production project management; project monitoring; cost management; and resource development. It acts as a comprehensive innovation hub and serves as a primary engine for ongoing development and advancement.

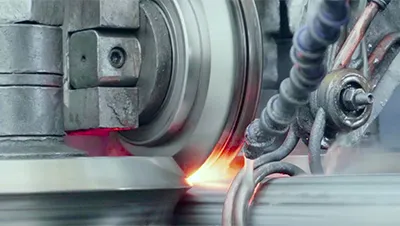

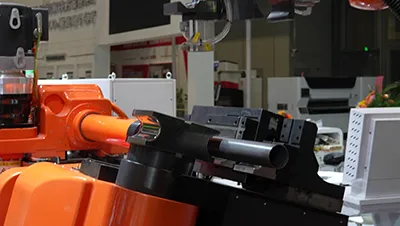

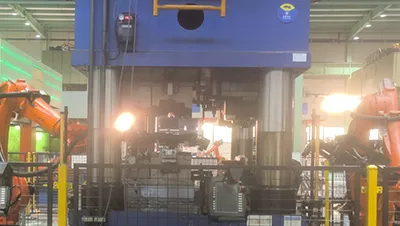

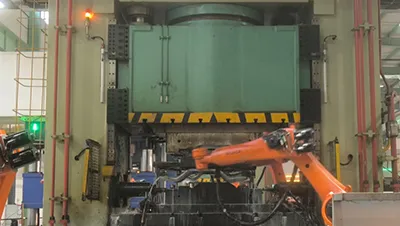

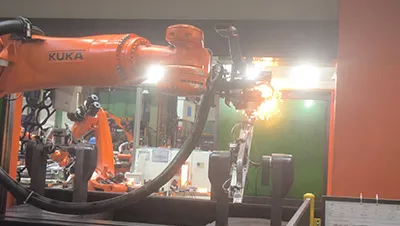

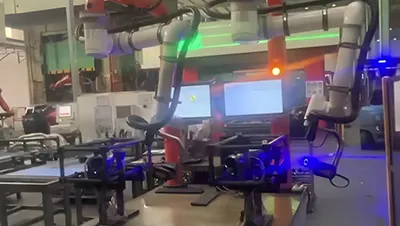

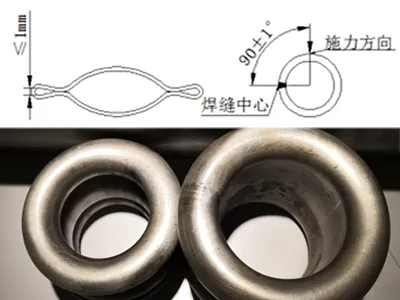

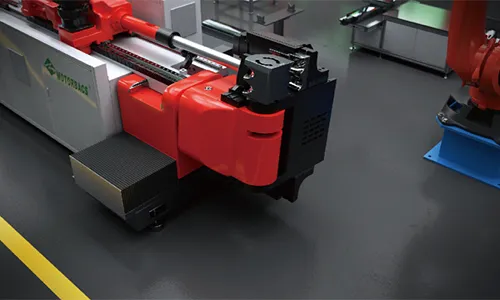

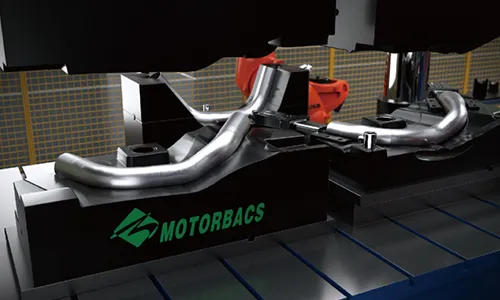

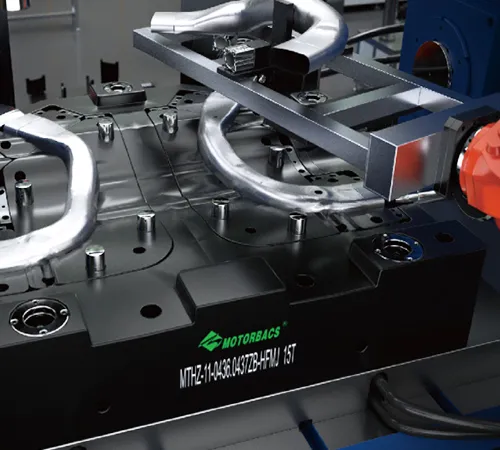

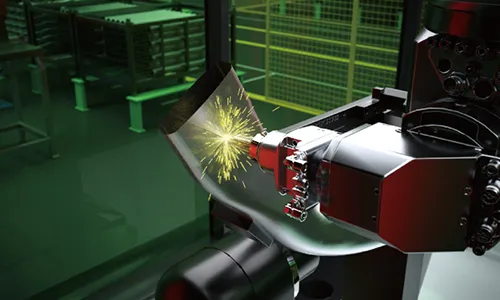

We have an experienced team of professional tooling and checking fixture design engineers. To date, more than two hundred sets of molds and checking fixtures have been designed for chassis torsion beam and trailing arm projects. The team is proficient in CAE analysis, 3D modeling software, and advanced surface design technologies. Current in-house tooling manufacturing capability includes three gantry machining centers, two high-speed milling machining centers, twenty-four vertical machining centers, four CNC lathes, and three wire-cutting machines. With these resources, all tooling and fixture processing and manufacturing work can be completed internally, with the exception of heat treatment and five-axis machining.