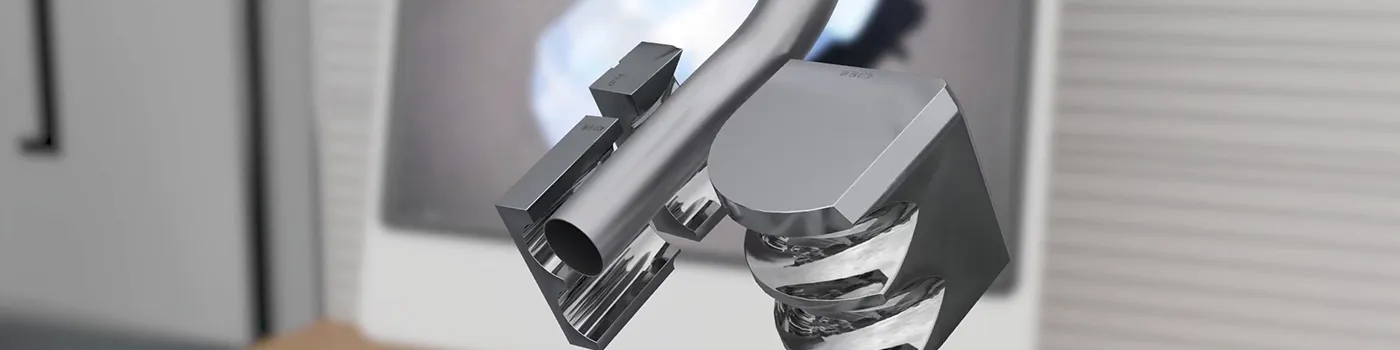

Automated Laser Scanning 3D Inspection Equipment

High-speed 3D laser scanner with robotic arm for complex metal components in automotive and industrial applications

3D laser scanning systems are used to capture the full surface geometry of metal parts with high accuracy. The 3D laser scanning and inspection system combines a laser scanner with a robotic arm and servo-driven motion, allowing complex parts to be scanned automatically as the robot follows a preset path. This setup enables continuous, real-time data capture, which is especially useful for checking shape accuracy and surface consistency on automotive and industrial components.

Request a Quote

Features

| Parameter | Standard Mode | Detailed Mode |

| Data acquisition rate | 2,650,000 measurements/s | 1,680,000 measurements/s |

| Laser projection | 22 blue laser lines + 1 deep-hole scanning line + 7 detail scanning lines | 22 blue laser lines + 1 deep-hole scanning line + 7 detail scanning lines |

| Laser safety class | Class 2 (eye-safe) | Class 2 (eye-safe) |

| Resolution (point spacing) | Up to 0.02 m | Up to 0.02 m |

| Accuracy | Up to 0.02 mm | / |

| Volumetric accuracy | 0.015 + 0.035 mm/m | / |

| Volumetric accuracy (with PhotoShot) | 0.015 + 0.015 mm/m | / |

| Hole position accuracy | Up to 0.03 mm | / |

| Hole position volumetric accuracy | 0.025 + 0.035 mm/m | / |

| Maximum depth of field | 550 mm | 550 mm |

| Scanner head weight | 1 kg | 1 kg |

| Data interface | USB 3.0 | USB 3.0 |

| Operating temperature | −20 to 40°C | −20 to 40°C |

| Maximum working range | Ø 2605 mm | Ø 2605 mm |